The "High-Temperature Corrosion Guard" of Industrial Furnaces

The "High-Temperature Corrosion Guard" of Industrial Furnaces

Industrial furnaces, as the "core heating equipment" in metallurgy, chemical, new energy, and other industries, face the triple challenges of 800-1200℃ high temperatures, corrosive flue gas erosion, and continuous load pressure year-round. Problems such as furnace tube oxidation and peeling, deformation of support structures, and corrosion and cracking of thermocouple sheaths not only lead to frequent equipment downtime for maintenance but also may cause potential safety hazards in production.

Among numerous heat-resistant materials, a nickel-based alloy named N06600 (UNS number, commercially known as Inconel 600) has become the standard material for critical components of industrial furnaces due to its characteristics of high-temperature resistance, corrosion and crack resistance, and long-term stability. We will comprehensively analyze: What exactly is N06600? Which parts can it be adapted to? And how does it solve the material selection pain points of industrial furnaces?

I. What is N06600 material?

N06600 is not an ordinary heat-resistant steel, but a classic nickel-based high-temperature alloy under the American ASTM standard.

72% Nickel (Ni): The cornerstone for high-temperature organizational stability, inhibiting hydrogen embrittlement and low-temperature phase transformation;

14-17% Chromium (Cr): Forms a protective barrier against oxidation and corrosion;

6-10% Iron (Fe): Balances mechanical properties and cost, enhancing processing plasticity.

Simply put, it inherits the high-temperature toughness of nickel-based alloys and also possesses the corrosion resistance of chromium, perfectly adapting to the complex demands of industrial furnaces that must withstand both high temperatures and corrosion.

II. For these critical parts of industrial furnaces, is N06600 indispensable?

In industrial furnaces, not all components require N06600, but high-temperature, high-load, high-corrosion core parts are almost inseparable from it. We will analyze the adaptation logic

by "component function":

III. Core Advantages: How does N06600 "withstand" harsh working conditions?

Material selection depends on the match between characteristics and working conditions. The 5 core advantages of N06600 precisely solve the 5 major material selection pain points of industrial furnaces:

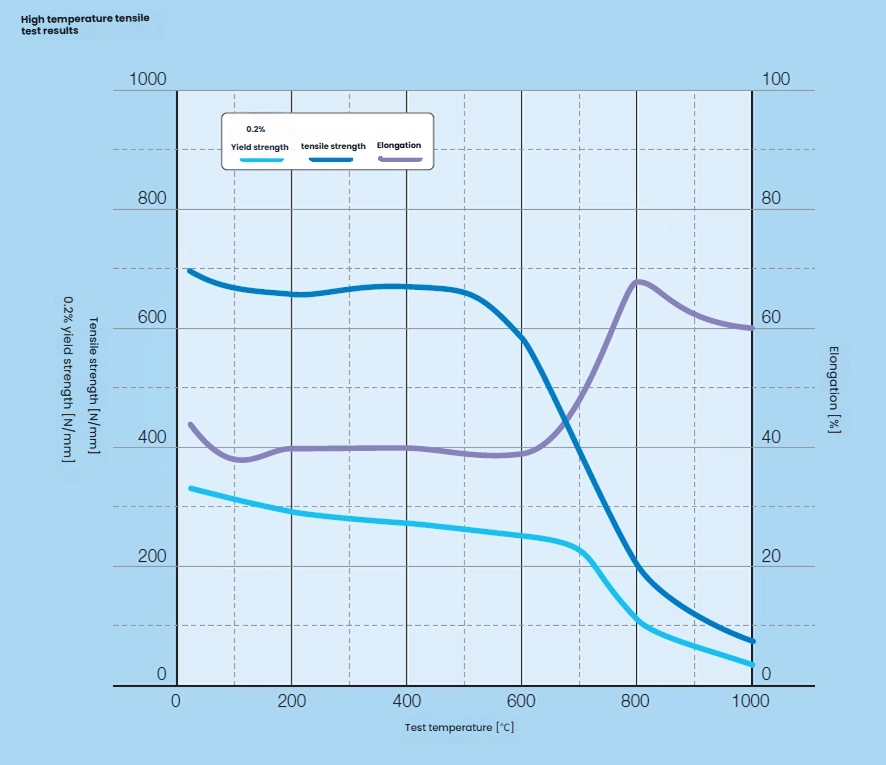

1.High-temperature oxidation resistance: Giving components an invisible protective coat.

In industrial furnaces, in air or oxygen-rich environments, ordinary steel (such as Q235) will rapidly oxidize and peel above 600℃. However, the 14-17% chromium element in N06600 forms a dense Cr₂O₃ oxide film on the surface – this film acts like an invisible protective coat, blocking oxygen from contacting the base metal. Even with continuous use at 1093℃, no significant oxidation loss will occur.

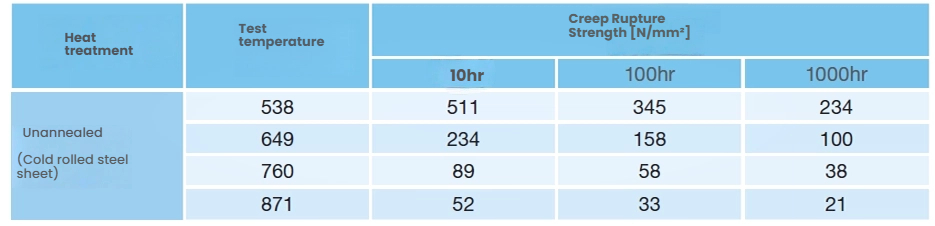

2.Creep resistance: Standing firm and undeformed at high temperatures.

The support structures and furnace tubes of industrial furnaces need to bear loads for a long time (e.g., weight of steel coils, medium pressure), and are prone to creep (slow plastic deformation, eventually leading to fracture) at high temperatures. The high nickel matrix + chromium element solid solution strengthening of N06600 gives it a 1000-hour creep strength of 100-150MPa at 650-980℃ (common range for industrial furnaces), which is 3 times that of ordinary 310S heat-resistant steel, fundamentally avoiding high-temperature deformation failure.

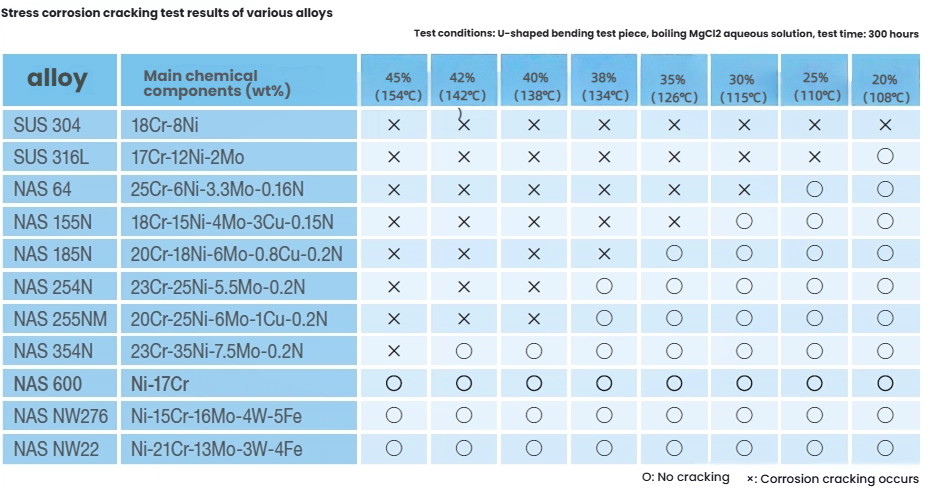

3.Corrosion resistance: The prevention of gnawing from acid mist and flue gas.

SO₂ in chemical cracking furnaces, Cl⁻ in waste incinerators, and the weak acidity of condensed water are all corrosion killers for components. The advantages of N06600 are:

For oxidative corrosion (air, oxygen-rich flue gas): Resisted by the Cr₂O₃ film;

For weakly reducing corrosion (CO, dilute sulfuric acid): High nickel matrix resists hydrogen embrittlement;

For local erosion corrosion: Uniform alloy structure without grain boundary chromium depletion, with no worries about pitting and cracking.

4.Long-term stability: No issues for 10 years

The design life of industrial furnaces is usually 10-20 years. The face-centered cubic structure of N06600 has no low-temperature phase transformation, and no brittle phases will precipitate even after long-term high-temperature exposure. Even after thousands of room temperature - 1000℃ temperature cycles, the mechanical property decay rate is less than 5%, significantly reducing the frequency of component replacement.

Key Material Support for Industrial Furnace Upgrades

In the trend of industrial furnaces upgrading towards better efficiency and low carbon, equipment demands higher stability and long life for critical components. N06600 can not only solve the current pain points of high-temperature corrosion and frequent maintenance but also adapt to future low-energy consumption and high-reliability operational needs.