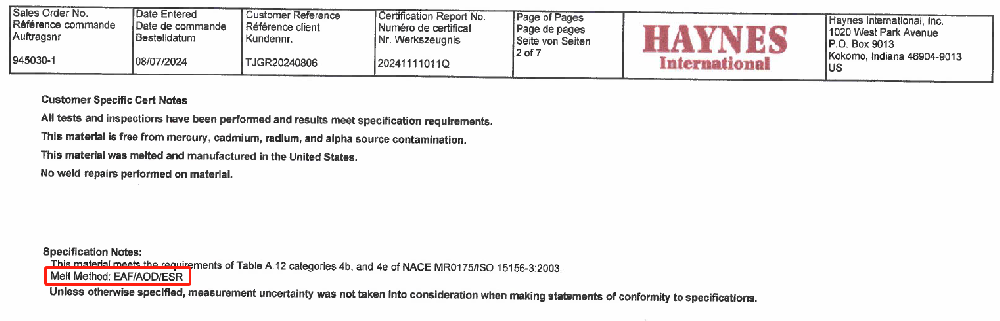

Decoding Nickel-Based Alloy Smelting Process: EAF + AOD + ESR

Decoding Nickel-Based Alloy Smelting Process: EAF + AOD + ESR

In the turbine blades of aerospace engines, corrosion-resistant pipelines in deep-sea oil and gas fields, and critical components of nuclear power plants, nickel-based alloys have become indispensable core materials in modern high-end manufacturing. This is due to their exceptional high-temperature strength, oxidation resistance, and corrosion resistance. The triple smelting process of EAF (Electric Arc Furnace) + AOD (Argon Oxygen Decarburization) + ESR (Electroslag Remelting) is the "unsung hero" behind the superior properties of nickel-based alloys and the standard technical route adopted by major global steel plants for producing high-end nickel-based alloys.

I. Nickel-Based Alloys: Smelting Challenges Behind High Performance

Nickel-based alloys have complex chemical compositions, typically containing high proportions of Ni (50%-70%), Cr (15%-30%), Mo (5%-10%), and other alloying elements, with some grades also incorporating reactive elements such as Al and Ti. This high degree of alloying delivers unique properties but also presents three major challenges in the smelting process:

Difficulty in Controlling Composition Uniformity: The mixture of multiple alloying elements can easily lead to compositional segregation during solidification, affecting the stability of material properties.

Prone to Loss of Reactive Elements: Elements like Al and Ti are highly susceptible to oxidation at high temperatures, with conventional smelting methods potentially causing a loss rate of 15%-20%.

Difficulty in Removing Inclusions: Nickel-based alloys are extremely sensitive to inclusions such as sulfides and oxides. For instance, the S content in Hastelloy C-276 must be strictly controlled below 0.002%; otherwise, corrosion resistance will be significantly compromised.

II. EAF + AOD + ESR: An Interlinked Precision Process System

To address these challenges, the triple process of EAF + AOD + ESR was developed, with each step playing a distinct role in producing high-quality nickel-based alloys.

EAF (Electric Arc Furnace): Efficient Melting and Preliminary Alloying

The electric arc furnace uses raw materials such as scrap steel, high-carbon ferrochromium, and electrolytic nickel to achieve preliminary alloying through precise proportioning. During smelting, bottom-blown argon and top-blown oxygen are employed to control the oxygen content in the furnace to below 2.0%, which reduces the oxidation loss of elements like Cr and Mo. Additionally, washing the furnace with low-impurity steel grades effectively removes residual harmful elements (e.g., Pb, Sn) from the furnace lining, preventing contamination of subsequent alloys.AOD (Argon Oxygen Decarburization): Precise Composition Control and Deep Refining

The AOD furnace blows an Ar-O₂ mixed gas into the molten pool, as argon can dilute the partial pressure of CO and achieve deep decarburization (C ≤ 0.01%) of temperatures around 1600°C while protecting Cr elements from oxidation. After decarburization, reactive elements such as Al and Ti are added, and reduction refining is conducted using ferrosilicon and lime to reduce the S content to below 0.001%, while precisely adjusting the molten steel temperature to 1620-1650°C.

ESR (Electroslag Remelting): Deep Purification and Microstructure Optimization

Electroslag remelting employs a ternary slag system of CaF₂-Al₂O₃-CaO to remove inclusions through slag-metal reactions and suppress the oxidation of reactive elements. By adjusting the current and voltage, the depth of the molten pool is precisely controlled to reduce elemental segregation.

III. The Triple Process: The Preferred Choice of Major Steel Plants

Major steel plants worldwide, particularly those in the United States, predominantly use the EAF + AOD + ESR triple process to produce nickel-based alloys. This process has become the industry standard due to its significant advantages:

Balance of Cost and Efficiency: EAF reduces raw material costs by utilizing scrap steel, AOD achieves efficient decarburization, and ESR improves yield rates, lowering overall costs by 20%-30% compared to traditional processes.

Enhanced Purity and Performance: The total inclusion content can be controlled below 10 ppm, with sulfur content ≤ 0.001%, significantly improving the alloy's corrosion resistance, high-temperature strength, and fatigue life.

Handling Large Tonnages: The EAF + AOD + ESR process is better suited for large-scale, high-tonnage production of nickel-based alloys, as the equipment capacity can be scaled up to meet industrial production demands.

The EAF + AOD + ESR triple process, with its precise technical logic and consistent quality performance, continues to supply critical materials for high-end manufacturing. As a core technology of major steel plants, it not only defines the quality standards for nickel-based alloys but also drives global high-end equipment manufacturing to new heights.

"Capturing one part per million of impurities in molten steel at 1700°C—this is the hardcore romance of human industrial civilization."