Decoding Creep Resistance: The Key to a Material's "Long-Term Durability"

In the field of materials engineering, we often focus on a material’s "short-term" properties such as strength, hardness, and toughness. However, in many industrial scenarios, materials are required to maintain stability under long-term stress and specific environmental conditions—and this is where a core indicator comes into play: creep resistance. From small components like automobile engine valves to large-scale parts such as aero-engine turbine blades and nuclear power equipment pressure vessels, a material’s creep resistance directly determines the service life and safety reliability of the equipment. Today, we will comprehensively break down the past and present of creep resistance, from its fundamentals to practical applications.

I. First, Understand: What is Creep? And What is Creep Resistance?

To grasp creep resistance, we must first clarify the concept of "creep":

Creep refers to the phenomenon where a material undergoes slow plastic deformation over time under constant temperature and constant stress—even when the stress is below the material’s yield strength. Simply put, it is a "fatigue" behavior where the material deforms slowly under the dual action of sustained stress and specific temperature.

Creep resistance, by contrast, is a material’s ability to resist this slow plastic deformation. The stronger the creep resistance, the better the material’s ability to maintain its original shape and performance under long-term stress and high-temperature environments, and the less likely it is to fail due to creep (e.g., excessive deformation, cracking, or fracture).

Here is a straightforward example: Boiler pipes operating at high temperatures bear long-term internal steam pressure. If their creep resistance is poor, the pipes will gradually thicken and thin, eventually leading to potential leakage. In contrast, materials with excellent creep resistance can maintain dimensional stability over decades of service.

II. Why is Creep Resistance So Important? These Scenarios Depend on It!

The importance of creep resistance stems entirely from the industrial demand for long-term high-temperature stress resistance. The following core fields have extremely strict requirements for a material’s creep resistance:

1. Aerospace Sector: The "Lifeline" of High-Temperature Components

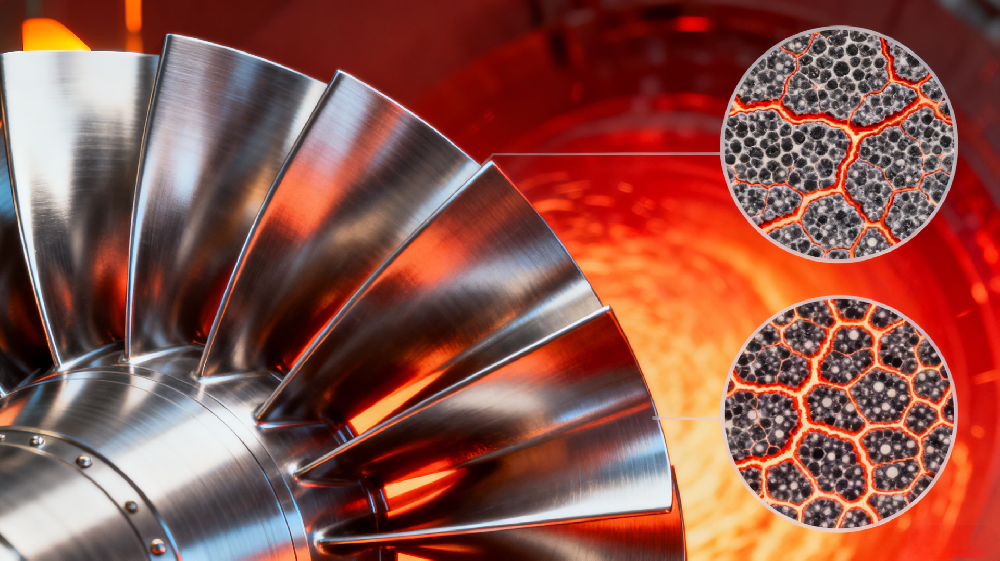

Aero-engine turbine blades not only withstand enormous centrifugal forces during operation but also endure the impact of high-temperature gas (exceeding 1000°C). If the blade material lacks sufficient creep resistance, even if it meets short-term strength standards, long-term use will cause "blade deformation", "tip wear", or even fracture due to creep—directly leading to engine failure. Currently, one of the core design goals for mainstream turbine blade materials is to enhance the creep limit.

2. Energy Sector: The "Safety Barrier" for Nuclear and Thermal Power Equipment

Pressure vessels of nuclear reactors, heat transfer tubes of steam generators, and superheater pipes of thermal power boilers need to operate at 300–600°C under long-term internal medium pressure, with a service life of 30–60 years. Significant creep in the material can cause structural failure of the equipment, leading to leakage or even more severe safety accidents. Therefore, such equipment must use heat-resistant steel or nickel-based alloys with excellent creep resistance.

3. Automotive Industry: The Durability Guarantee for the Engine "Heart"

Components such as automobile engine valves and piston tops operate at temperatures of 600–800°C while enduring reciprocating impact stress. If the material has poor creep resistance, the valves will gradually lengthen (causing seal failure), and the piston tops will deform due to creep (affecting combustion chamber volume). Ultimately, this leads to reduced engine power, increased fuel consumption, or even engine scrapping.

III. Key Factors Influencing Creep Resistance

A material’s creep resistance is not innately fixed; it is affected by both the material’s intrinsic properties and the external service environment. The core influencing factors can be summarized as follows:

1. Material Composition: The Innate Foundation of Creep Resistance

Role of Alloying Elements: Pure metals generally have poor creep resistance, but adding specific alloying elements can significantly improve it. For example, adding chromium (Cr), molybdenum (Mo), or vanadium (V) to steel forms stable carbides (e.g., Mo₂C, VC). As creep occurs from the directional migration of atoms, these fine carbides can inhibit creep by blocking the movement of atoms inside the metal. In nickel-based superalloys, adding tungsten (W) or rhenium (Re) enhances the alloy’s high-temperature strength and atomic bonding force, further improving creep resistance.

Impact of Impurities: Impurity elements such as sulfur (S) and phosphorus (P) form low-melting-point compounds at grain boundaries, causing grain boundary softening which accelerates creep (grain boundaries are the main channels for atomic migration). Therefore, materials requiring creep resistance must have strictly controlled impurity content.

2. Microstructure: The "Core Tool" for Regulating Creep Resistance

A material’s microstructure (e.g., grain size, grain boundary state, and precipitate distribution) exerts a significant influence on creep behavior:

Grain Size: While fine-grained materials have higher strength at low temperatures, coarse-grained materials exhibit better creep resistance in high-temperature scenarios. This is because fine grains have more grain boundaries, allowing atoms to migrate along the boundaries more easily (accelerating creep), whereas coarse grains have fewer boundaries and greater resistance to atomic migration. For instance, aero-engine turbine blades adopt a single-crystal structure (no grain boundaries) to completely eliminate the impact of grain boundary creep.

Precipitates: As mentioned earlier, fine, uniformly distributed precipitates in alloys (e.g., carbides or intermetallic γ’ phases) act like nails to pin dislocations inside the metal (dislocation movement is the root cause of plastic deformation). This blocks dislocation slip at high temperatures, thereby significantly enhancing creep resistance. For example, the γ’ phase (Ni₃Al) in nickel-based superalloys remains stable at high temperatures and is the core mechanism behind their creep resistance.

3. External Environment: The "Dual Test" of Temperature and Stress

Temperature: Temperature is the most critical external factor affecting creep. Higher temperatures increase atomic kinetic energy, making directional atomic migration more likely—resulting in an exponential increase in creep rate. For example, a heat-resistant steel may creep extremely slowly at 400°C, but its creep rate could increase by more than 100 times when the temperature rises to 600°C.

Stress: Higher stress increases the driving force for dislocation movement and atomic migration inside the material, accelerating creep deformation. Notably, even if the stress is below the material’s room-temperature yield strength, significant creep can still occur if the temperature is sufficiently high (known as "high-temperature low-stress creep").

4. Time: The Cumulative Effect of Creep

Creep is a typical time-dependent deformation. Under the same temperature and stress, longer durations lead to greater cumulative creep deformation. The material may even transition from slow deformation to the accelerated creep stage, eventually resulting in creep fracture. Therefore, the evaluation of creep resistance must incorporate long-term aging tests.

Although creep resistance may seem like a niche material indicator, it underpins the core demand for long-term safe operation of industrial equipment. From the precise control of material composition to the refined design of microstructures and the continuous optimization of testing methods, every breakthrough in creep resistance drives high-end equipment toward higher temperatures, greater reliability, and longer service life.