Differences Between Nickel-Molybdenum Alloys B-2 and B-3

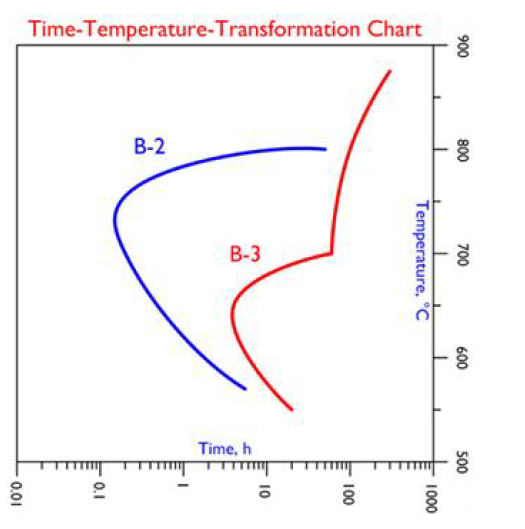

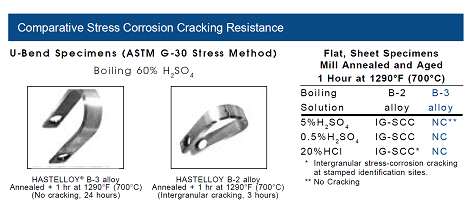

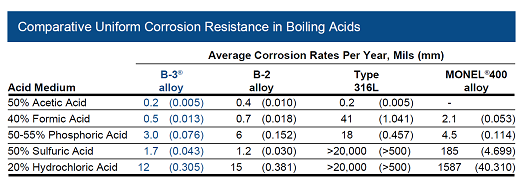

Differences Between Nickel-Molybdenum Alloys B-2 and B-3 Within the nickel-molybdenum alloy family, B-2 and B-3 have garnered significant attention. B-3, as an enhanced and upgraded version of B-2, carries forward its legacy while introducing innovations. Let's delve into their differences. I. Review of Basic Characteristics of B-2 Alloy (I) Composition and Performance Advantages Table 1: Chemical Composition of B-2 Alloy (ASTM B333 UNS N10665) Table 2: Physical Properties of B-2 Alloy Table 3: Mechanical Properties of B-2 Alloy Alloy B-2 possesses the following characteristics: Controls iron and chromium elements to minimal levels to inhibit the formation of the β phase Ni₄Mo. Excellent corrosion resistance in reducing environments. Outstanding resistance to corrosion by moderate concentrations of sulfuric acid and many non-oxidizing acids. Very good resistance to chloride-induced reduction of stress corrosion cracking (SCC). Excellent resistance to various organic acids. (II) Applications and Processing Key Points Chemical and Petrochemical: Hydrochloric acid synthesis furnaces, sulfuric acid evaporators, acetic acid reactors, chloride medium transfer pipelines. Energy and Environmental Protection: Corrosion-resistant parts for waste incinerators, acid gas treatment equipment, industrial wastewater treatment systems. Pharmaceutical and Food: High-purity corrosive media storage tanks, reaction kettles (meeting food-grade sanitary standards). Marine Engineering: Offshore platform acid seawater treatment equipment, including components resistant to H₂S corrosion in oil and gas extraction. Hot Working: The hot working temperature range for alloy B-2 is 1160°C to 900°C, with water quenching as the cooling method. To ensure optimal corrosion resistance, annealing should be performed after hot working. During hot working, the workpiece should be directly placed into a pre-heated furnace. Cold Working: Cold working should be performed in the solution-annealed condition. The work hardening rate of alloy B-2 is higher than that of austenitic stainless steel, thus requiring corresponding adjustments to the processing equipment. Intermediate annealing is necessary during cold working processes. If the cold deformation rate exceeds 15%, solution treatment is required before use. Welding Process: Use low heat input GTAW (TIG) welding. ERNiMo-7 filler metal is recommended. Interpass temperature should be ≤ 120°C. II. Upgrade Logic of B-3 Alloy: Addressing B-2 Pain Points After HASTELLOY® B-2 was introduced to the market, issues such as welding and heat treatment cracking and stress corrosion cracking in the weld heat-affected zone (HAZ) became apparent. Similar problems were encountered during production processes like hot rolling and heat treatment. As an upgraded version, the core purpose of B-3 is to specifically address these pain points. III. Key Differences Between B-2 and B-3 (I) Composition Fine-Tuning The main characteristic of B-3 alloy is its greatly improved structural stability (particularly reduced sensitivity to Ni-Mo phase formation). The Time-Temperature-Transformation (TTT) diagram shown below in Figure 1 illustrates the advantages of B-3 alloy over its predecessor (B-2 alloy). B-2 alloy rapidly forms Ni-Mo phases around 750°C, whereas B-3 alloy requires several hours (around 650°C) to induce the harmful secondary phases. This is achieved through the judicious use of trace elements and adjustments in molybdenum content, promoting the slow formation of Ni-rich phases rather than Mo-rich phases. Figure 1. Time-Temperature-Transformation Chart for the two alloys: B-2 and B-3. (II) In the last two decades, almost all new construction equipment and repair equipment have adopted B-3 to replace the older B-2. The B-3 alloy test data from Haynes International's is publicly available and shown below for reference.