Introduction to Titanium-Palladium Alloy GR11 for Plate Heat Exchangers

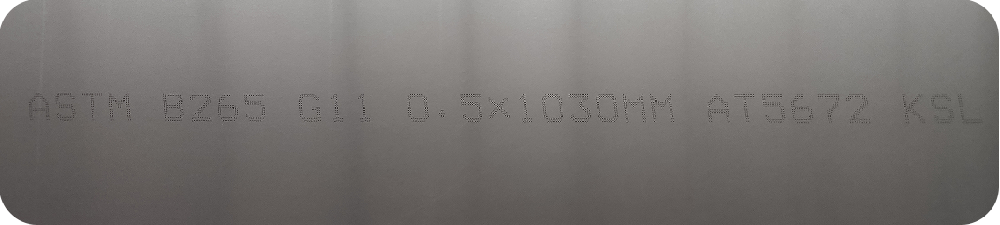

Introduction to Titanium-Palladium Alloy GR11 for Plate Heat Exchangers ASTM B265 is the American standard specification for titanium and titanium alloy plates, sheets, and strips. GR11 (commonly referred to as Ti-0.15Pd alloy) is a titanium-palladium alloy based on pure titanium with the addition of approximately 0.12%–0.25% palladium (Pd). The incorporation of palladium significantly enhances corrosion resistance, making it particularly suitable for heat exchangers and other applications requiring resistance to harsh media. Below is a detailed description of its specific properties and uses: Titanium (Ti): Balance (≥99.6%) Palladium (Pd): 0.12%–0.25% (key alloying element for improved corrosion resistance) Impurity Limits (≤%): Iron (Fe ≤ 0.25), Carbon (C ≤ 0.08), Nitrogen (N ≤ 0.03), Hydrogen (H ≤ 0.015), Oxygen (O ≤ 0.18). Low impurity levels ensure material purity and stability. Tensile Strength: ≥485 MPa (higher than pure titanium GR2’s 345 MPa, offering superior mechanical strength for pressure-bearing applications) Yield Strength: ≥345 MPa (maintains good structural strength after forming, with strong resistance to deformation) Elongation: ≥15% (good ductility, facilitating rolling, bending, and welding assembly of heat exchangers while reducing the risk of cracking during processing) Resistance to Reducing Media: Pure titanium is prone to pitting or crevice corrosion in reducing acids (e.g., hydrochloric acid, sulfuric acid) or neutral/acidic media containing chloride ions. The addition of palladium enhances corrosion resistance in reducing environments through a "cathodic protection" effect, forming a stable passive film on the material surface (e.g., corrosion rates are significantly lower than those of pure titanium in hydrochloric acid ≤100°C and concentration ≤15%, or in industrial wastewater and condensate containing Cl⁻). Resistance to Crevice Corrosion: Sealing gaps between heat exchanger plates and welded joints are susceptible to crevice corrosion due to media stagnation. The palladium alloying in GR11 effectively inhibits such corrosion, extending equipment service life. Temperature Resistance: Applicable temperature range of -253°C to 315°C, covering most industrial heat exchanger operating conditions (e.g., chemical processing at moderate temperatures, food processing heating/cooling, seawater heat exchange). GR11 titanium-palladium alloy sheets are ideal for manufacturing heat exchangers handling corrosive media due to their combination of high strength, excellent corrosion resistance, and good processability. Specific application scenarios include: Chemical Industry Heat Exchangers Heat exchange involving acidic media: e.g., cooling/heating exchangers for hydrochloric acid, dilute sulfuric acid, or organic acids (e.g., acetic acid) in synthetic ammonia, pesticide, and dye production. Replaces traditional stainless steel or pure titanium, which are prone to corrosion, ultimately reducing maintenance frequency. Chlor-alkali industry: Used in heat exchangers for brine and chlorine gas condensation, resisting corrosion from Cl⁻-containing media and preventing leaks or equipment failure due to corrosion. Pharmaceutical/Food Processing Heat Exchangers Heat exchange for corrosive solvents (e.g., ethanol, citric acid solutions) in pharmaceuticals: Titanium-palladium alloy is non-toxic and has a smooth surface, complying with food and drug hygiene standards (FDA-approved). It also resists solvent corrosion, making it suitable for clean plate heat exchangers. Heating/sterilization exchangers for acidic food materials (e.g., tomato juice, fruit juice): Resists organic acid corrosion, preventing metal ion leaching and material contamination. Seawater/Brackish Water Heat Exchange Scenarios Condensers/heat exchangers in coastal power plants and desalination plants: Seawater contains high Cl⁻ concentrations (~3.5%). GR11 resists long-term erosion corrosion and crevice corrosion in seawater, offering greater durability than copper alloys (prone to scaling and corrosion) and lighter weight (density ~4.5 g/cm³, half that of steel), reducing load on support structures. Other Industrial Heat Exchange Applications Heat exchangers for electroplating wastewater treatment: Handles heat exchange for wastewater containing heavy metal ions and acids, resisting corrosion and reducing equipment replacement costs. Paper industry: Used for heat exchange in pulp black liquor and bleaching solutions, resisting corrosion from sulfates and chlorine-based bleaching agents. The core value of ASTM B265 GR11 titanium-palladium alloy sheets lies in addressing the limitations of pure titanium in reducing/chloride-containing media through palladium alloying, while retaining the advantages of titanium: light weight, high strength, and processability. Thus, it is an ideal material for heat exchangers handling corrosive media, particularly in industries with stringent corrosion resistance requirements such as chemical processing, pharmaceuticals, and seawater utilization.I. Key Properties of ASTM B265 GR11

1. Chemical Composition (Major Elements, as per Standard Requirements)

2. Mechanical Properties (Typical Values for Sheets, Compliant with ASTM B265)

3. Key Performance: Corrosion Resistance (Core Advantage for Heat Exchanger Applications)

II. Core Applications in Heat Exchangers and Suitable Scenarios

Conclusion