Introducing Inconel® 617: The "Versatile Champion" of High-Temperature Alloys

1. Composition Design: A Multi-Element "High-Temperature Defense System"

The chemical composition of Inconel 617 (UNS N06617) represents an "optimal solution" for high-temperature environments:

Nickel Matrix (~50%): Provides an excellent foundation for toughness and corrosion resistance.

Chromium (20-22%): Forms a dense Cr₂O₃ oxide film to resist high-temperature oxidation.

Cobalt (10-15%): Enhances high-temperature strength via solid solution strengthening.

Molybdenum (8-10%): Improves corrosion resistance in reducing environments.

Aluminum (0.8-1.5%): Works synergistically with chromium to form spinel oxides, improving resistance to oxide scale spallation.

This unique combination allows Alloy 617 to maintain stable mechanical properties even at 1200°C. The secret lies in two key mechanisms: Solid Solution Strengthening

cobalt and molybdenum atoms embed within the nickel lattice, hindering dislocation movement; and Oxidation Protection – aluminum preferentially oxidizes to form an inner barrier layer, preventing oxygen diffusion into the base metal.

2. Performance Profile: "All-Around Performance" from Room Temperature to 1200°C

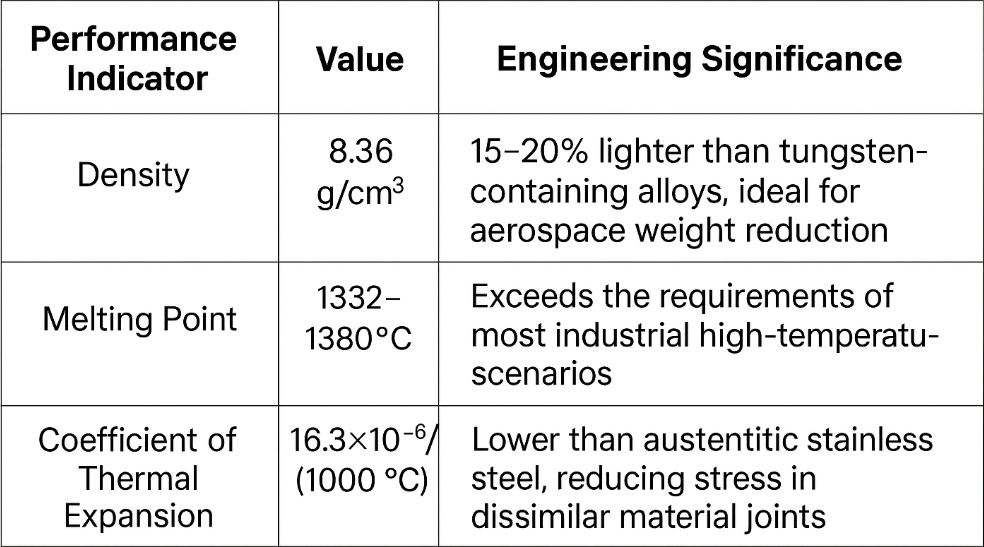

2.1 Physical Properties: Balancing Lightweight Design and Heat Resistance

2.2 Mechanical Properties: The "Benchmark" for High-Temperature Strength

Room Temperature Tensile: Tensile strength ≥734 MPa, elongation ≥62%, demonstrating exceptional toughness.

2.1 Physical Properties: Balancing Lightweight Design and Heat Resistance

High-Temperature Tensile: Maintains tensile strength of 662 MPa at 1000°C – over 3 times higher than standard stainless steel.

Creep Performance: Under 1095°C/100 MPa conditions, creep strain <1% after 1000 hours, suitable for long-term load-bearing applications.

2.3 Environmental Resistance: The "Dual Champion" of Oxidation & Corrosion Resistance

Cyclic Oxidation Test: Weight change <10 mg/cm² after cycles of 15 min heating + 5 min cooling at 2000°F (1095°C), outperforming Inconel 600/625.

Carburization Resistance: Weight gain of only 10 g/m² after 25 hours in methane atmosphere at 1095°C – one-seventh the weight gain of Alloy X.

Aqueous Corrosion Resistance: Excellent performance in caustic soda, nitric acid, and other media. While primarily used at high temperatures, its corrosion resistance at ambient temperatures is also outstanding.

3. Engineering Applications: A "Cross-Industry Star" from Aerospace to Energy Infrastructure

3.1 Core Components in Aero Gas Turbines

Combustion Chambers & Transition Ducts: Withstand 1800°F (980°C) hot gas impingement, requiring simultaneous resistance to oxidation and thermal fatigue.

Turbine Guide Vanes: Maintain structural integrity and resist creep deformation in environments above 1200°C.

Key Advantage: Compared to traditional alloys, 617 can extend component life by 30% while reducing weight by 15%.

3.2 Energy & Chemical Processing Sectors

Nuclear Power Plant Steam Generators: Resists corrosion in high-temperature, high-pressure steam/water environments, meeting ASME certification.

Catalyst Support Grids for Nitric Acid Production: Remains stable in nitrogen oxide atmospheres, replacing traditional stainless steel and reducing replacement frequency.

Coal Gasification Reactors: Withstands erosion from high-temperature gases containing sulfur and carbon, lowering equipment maintenance costs.

3.3 Advanced Manufacturing Scenarios

Heat Treatment Baskets: Repeatedly cycled in and out of furnaces at 1100°C, demanding both strength and thermal shock resistance.

Molybdenum Reduction Boats (H₂ Atmosphere): Does not react with molybdenum during hydrogen reduction, ensuring product purity.

Jet Engine Bolts: Endure cyclic loading and high-temperature oxidation, requiring simultaneous strength and fatigue resistance.

4. Manufacturing Processes: "Precision Control" from Melting to Forming

4.1 Hot & Cold Working

Hot Working Temperature: 1010-1205°C (1850-2200°F). Requires higher forging forces but offers good formability.

Cold Working Characteristics: High work hardening rate necessitates intermediate annealing (1040°C) to restore ductility.

Critical Control: Grain size control (ASTM 3-6) to balance creep strength and low-cycle fatigue performance.

4.2 Heat Treatment Optimization

Solution Annealing: 2150°F (1175°C) hold followed by water quench produces coarse grains (ASTM 2.5-4), maximizing creep strength.

Grain Size Control: Thermomechanical processing optimizes grain size to ASTM 4-5, increasing low-cycle fatigue life by 200%.

5. Technical Comparison: 617 vs. Other High-Temperature Alloys

Conclusion: Inconel 617 demonstrates the most balanced strength - corrosion resistance - oxidation resistance profile.

It is particularly well-suited for complex operating conditions demanding both high-temperature load-bearing capability and environmental durability.