Hastelloy® G-30 Alloy — Superior Corrosion Resistance for Aggressive Environments

Hastelloy® G-30 is a high-performance nickel-based alloy engineered to withstand severe corrosive and high-temperature environments. Its advanced chemical composition and robust mechanical properties make it an ideal material for chemical processing, oil & gas, marine engineering, and other demanding industries. Ruisen proudly offers precision-cut and custom-fabricated G-30 alloy products tailored to your critical applications.

1. Chemical Composition & Microstructure

2. Key Performance Benefits

Exceptional Corrosion Resistance

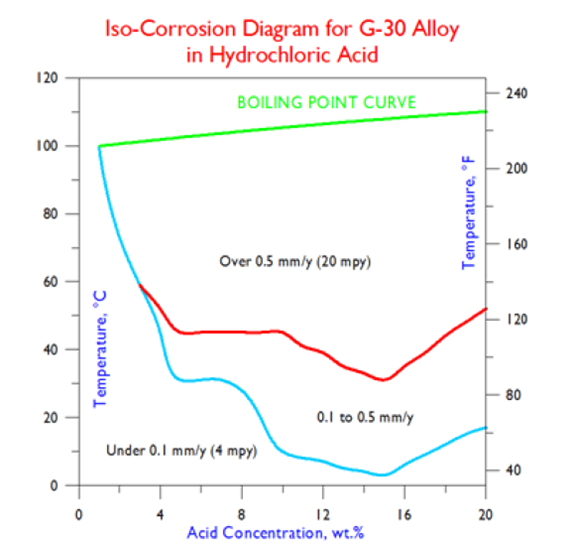

Strong Acid Environments: In wet-process phosphoric acid containing Cl⁻ and F⁻, G-30 exhibits a corrosion rate as low as 0.025–2.5 mm/year—2 to 10 times better than Alloy G-3 and Alloy 625. Outstanding resistance in nitric + hydrofluoric acid mixtures.

High-Temperature Stability: Performs reliably at 1000–1100°C with excellent oxidation resistance.

Stress Corrosion Cracking Resistance: Superior resistance to chloride-induced SCC, especially in marine and chloride-rich environments.

Outstanding Mechanical Properties

High Strength: Tensile strength of 760–870 MPa, yield strength of 345–415 MPa, with elongation of 40–45%.

Thermal Strength: Maintains mechanical integrity at elevated temperatures—outperforming conventional stainless steels.

Excellent Fabrication & Weldability

Formability: Supports both cold and hot working (stamping, bending, forging, rolling) with moderate work hardening.

Welding: Recommended processes include GTAW (TIG) and GMAW (MIG) with ERNiCrMo-11 filler metals. Avoid SAW (submerged arc welding) to minimize heat input. Post-weld solution annealing at 1177°C (air or water quench) restores corrosion resistance.

3. Typical Applications

Chemical Processing

Phosphoric Acid Production: Evaporators, reactors, and pipelines—particularly suited for fluoride-rich wet-process systems.

Acid Pickling Equipment: Ideal for nitric/hydrofluoric acid-based pickling tanks and heat exchangers.

Aggressive Media Handling: Tanks and reactors for sulfuric, nitric, and formic acid service.

Oil & Gas

Sour Gas Wells: Components exposed to H₂S and CO₂-rich environments.

Refinery Equipment: Reactors and separators operating under high pressure and temperature.

Marine Engineering

Seawater Systems: Desalination units and offshore platform piping, offering excellent chloride corrosion resistance.

Ship Components: Pumps, valves, and seawater-contacting parts.

Nuclear Industry

Waste Management: Storage containers and processing equipment for radioactive and corrosive materials.

4. Comparison with Other Alloys

5. Processing Notes

Work Hardening: Cold forming may induce stress; intermediate annealing is recommended.

Cutting Techniques: Use laser or waterjet cutting; avoid flame cutting to prevent surface oxidation.

Surface Preparation: Clean thoroughly before welding to eliminate oil and oxides and prevent weld defects.

6. Standards & Certifications

Hastelloy® G-30 complies with major international standards:

ASTM: B366 (fittings), B581 (bars), B619 (welded pipes)

Corrosion Standards: NACE MR0175 (for sour oil & gas environments)

Equivalent Grades:

UNS N06030 (ASTM)

DIN 2.4603 (Germany)

NS3404 (China)

Conclusion

With its high-chromium formulation and balanced alloying elements, Hastelloy® G-30 delivers unparalleled corrosion resistance and mechanical durability in extreme environments. Ruisen proudly supplies this premium alloy for mission-critical applications in chemical processing, energy, and marine sectors—ensuring long service life and performance reliability where it matters most.

For technical datasheets or project consultations, please contact Ruisen Special Steel.