Corrosion Resistance Properties of Monel Alloy

Monel alloy (Monel) is a nickel-based, copper-containing corrosion-resistant alloy (typical grades such as Monel 400, containing approximately 65%-70% nickel, 20%-29% copper, and small amounts of iron, manganese, etc.). Due to its excellent corrosion resistance, it is widely used in chemical, marine engineering, and other fields. Its corrosion resistance characteristics are as follows:

I. Resistance to Various Media

Excellent Resistance to Water and Aqueous Solutions

Freshwater and Seawater: In ambient freshwater, seawater, and humid atmospheres, it exhibits almost no corrosion, with an extremely low corrosion rate (typically < 0.025 mm/year). This makes it suitable for manufacturing ship components, seawater desalination equipment, underwater pipelines, etc.

Neutral or Weakly Alkaline Solutions: It shows good corrosion resistance to weakly alkaline solutions such as sodium hydroxide and sodium carbonate (at low concentrations), making it suitable for alkali treatment equipment.

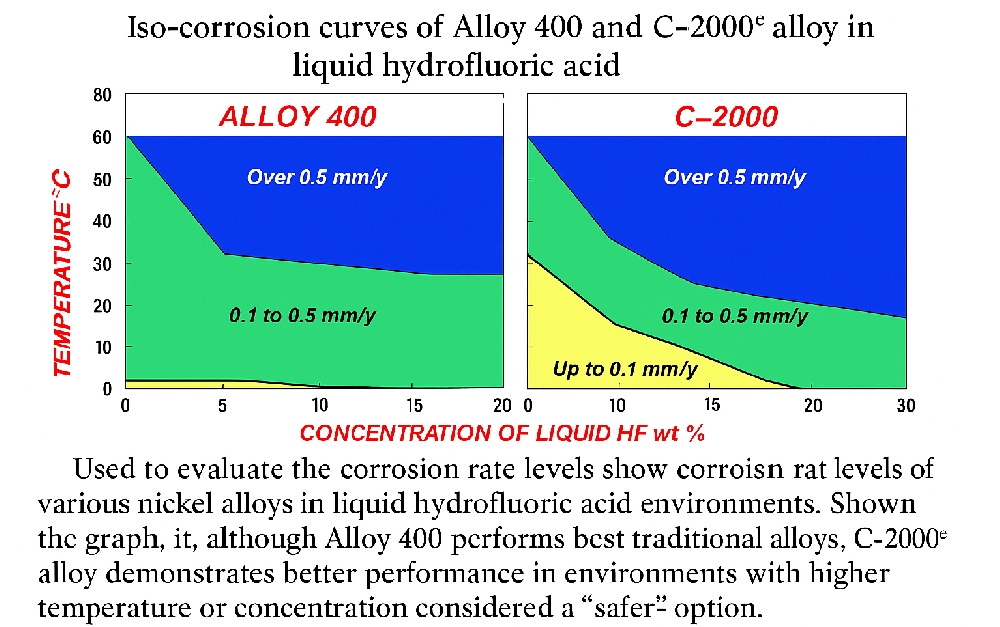

Hydrofluoric Acid (HF): This is one of the most outstanding properties of Monel alloy. It exhibits extremely strong corrosion resistance to hydrofluoric acid across all concentrations and temperatures (including anhydrous hydrofluoric acid). This is because nickel does not react with fluorine, and the presence of copper inhibits corrosion. Monel is the material of choice for HF-related equipment (e.g., fluorination reactors, pipelines).

Resistance to Certain Acids

Non-Oxidizing Acids: It has moderate resistance to dilute hydrochloric acid and dilute sulfuric acid, but the corrosion rate increases with higher concentrations and temperatures. It performs well with phosphoric acid, especially at low temperatures and concentrations.

Oxidizing Acids: It has poor resistance to strong oxidizing acids such as nitric acid and concentrated sulfuric acid, as these acids can destroy the passive film on the alloy surface, accelerating corrosion.

Resistance to Gases and Organic Substances

Dry Gases: It resists corrosion well in dry chlorine, hydrogen chloride, sulfur dioxide, and other gases. However, in humid conditions (e.g., moisture-containing chlorine), corrosion resistance decreases due to the formation of corrosive media.

Organic Substances: It exhibits excellent resistance to most organic solvents (e.g., alcohol, benzene, petroleum products), making it suitable for chemical storage tanks, pumps, valves, etc.

II. Resistance to Localized Corrosion

Pitting and Crevice Corrosion: In chloride-containing environments (e.g., seawater), its resistance to pitting and crevice corrosion is superior to that of ordinary stainless steel. However, prolonged exposure to high chloride concentrations or elevated temperatures may still lead to localized corrosion.

Intergranular Corrosion: Monel alloy inherently has strong resistance to intergranular corrosion, especially after proper heat treatment, reducing susceptibility to intergranular corrosion caused by grain boundary precipitation (unlike some stainless steels).

Stress Corrosion Cracking (SCC): It has low susceptibility to SCC in most media (e.g., seawater, dilute acids). However, under specific conditions (e.g., high-temperature ammonia environments), there may be some risk.

III. Corrosion Resistance at High Temperatures

In air, Monel alloy can withstand high-temperature oxidation up to approximately 480°C. Beyond this temperature, an oxide film forms on the surface, but the oxidation rate remains low, maintaining some corrosion resistance.

In high-temperature reducing atmospheres (e.g., sulfur-containing gases),its corrosion resistance is better than that of many stainless steels. However, prolonged high-temperature use requires attention to changes in mechanical properties.

Summary

The corrosion resistance of Monel alloy stems primarily from the stability of nickel and the synergistic effect of copper. It performs exceptionally well in hydrofluoric acid, seawater, and neutral/weakly alkaline media, making it a critical material for handling corrosive environments in chemical, marine, and pharmaceutical industries. However, its sensitivity to strong oxidizing acids must be noted, and practical applications should be evaluated based on specific media, temperature, concentration, and other conditions.