Overview of NACE International Standards for Metallic Materials

NACE International (formerly the National Association of Corrosion Engineers) is an authoritative worldwide organization in the field of corrosion control. Founded in 1943, it is headquartered in Houston, Texas, USA, and still is relevant to the oversight and control of metallic materials produced today. As the world's largest professional organization dedicated to corrosion, NACE has long been committed to the research and development of corrosion control technologies. It has established a systematic and rigorous standards system for metallic materials, providing effective guidelines for material selection and construction in industries such as petrochemicals, marine, and chemicals.

1. Core Content and Classification of Metal Material Standards

The metal material standards developed by NACE focus on corrosion resistance, particularly for the selection and application of materials in harsh environments containing hydrogen sulfide (H2S) and carbon dioxide (CO2). The following are its key standards:

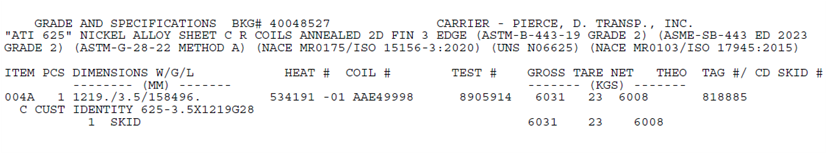

1. NACE MR0175/ISO 15156

Positioning: Serves as an international benchmark for the selection of materials in H2S-containing environments in the oil and gas industry, covering carbon steels, low alloy steels, cast irons and corrosion resistant alloys (CRAs).

Structure:

Part 1: General principles for the selection of crack-resistant materials, which requires these materials must pass laboratory tests (such as NACE TM0177 for sulfide stress cracking and NACE TM0284 for hydrogen-induced cracking).

Part 2: Crack resistance requirements for carbon steel, low alloy steel and cast iron, including hardness limits (such as carbon steel ≤ HRC 22) and specified welding procedures.

Part 3: Application guidelines for corrosion-resistant alloys (e.g. nickel-based alloys, stainless steels), providing material selection charts for different H2S partial pressures and temperature ranges.

2. NACE MR0103/ISO 17945

Positioning: A standard for resistance to sulfide stress cracking (SSC) of metallic materials in acidic environments in the refining industry, filling the gap left by NACE MR0175 in the refining sector.

Key Features:

- Specifies carbon steel welding control requirements, which must comply with NACE RP0472 regarding the hardness of the heat-affected zone (HAZ).

- Does not address chloride stress corrosion cracking, focusing solely on the assessment of sulfide stress cracking (SSC) risks.

3. Other Standards

NACE SP0402-2023: Standard for the construction and quality control of fusion-bonded epoxy (FBE) coatings on pipeline girth welds to ensure long-term corrosion resistance in underground environments.

NACE TM21423-2023: Test method for determining temperature limits of insulating coatings, used in the design of personnel protection for high-temperature equipment.

2. Core Purpose of the Standards

1. Material Selection and Risk Control

In deep-sea and high-pressure H2S/CO2 mixed environments, selecting duplex stainless steel that meets MR0175 standards (such as 22Cr grade) can effectively mitigate sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC).

In refining units, carbon steel vessels and pipelines must strictly follow MR0103 welding specifications. Measures such as preheating, post-weld heat treatment, or reducing the carbon equivalent are required to minimize the risk of heat-affected zone (HAZ) embrittlement.

2. Manufacturing and Construction Specifications

Welding Procedures:

- Strict control of the chemical composition and sulfur content of welding materials.

- Post-weld heat treatment (PWHT) or limitation of carbon equivalent (e.g., CE ≤ 0.45) to eliminate residual stress.

Coating Protection:

- Construction should follow SP0402 requirements for surface preparation, coating thickness and curing conditions.

- For girth weld areas, dual-layer protection may be applied—thermal spray followed by FBE (fusion-bonded epoxy) coating.

3. Implementation Effectiveness and Outlook

Scientific corrosion management can reduce operation and maintenance costs by about 35% and improve equipment safety and reliability. Driven by stringent standards, new materials such as nickel-based alloys and super austenitic steels continue to emerge. Looking ahead, companies should thoroughly understand and strictly implement NACE standards to support industrial upgrading and green development.