Plate Heat Exchanger Plate Thickness Selection: The Technical Logic of Balancing Safety, Efficiency, and Application Suitability

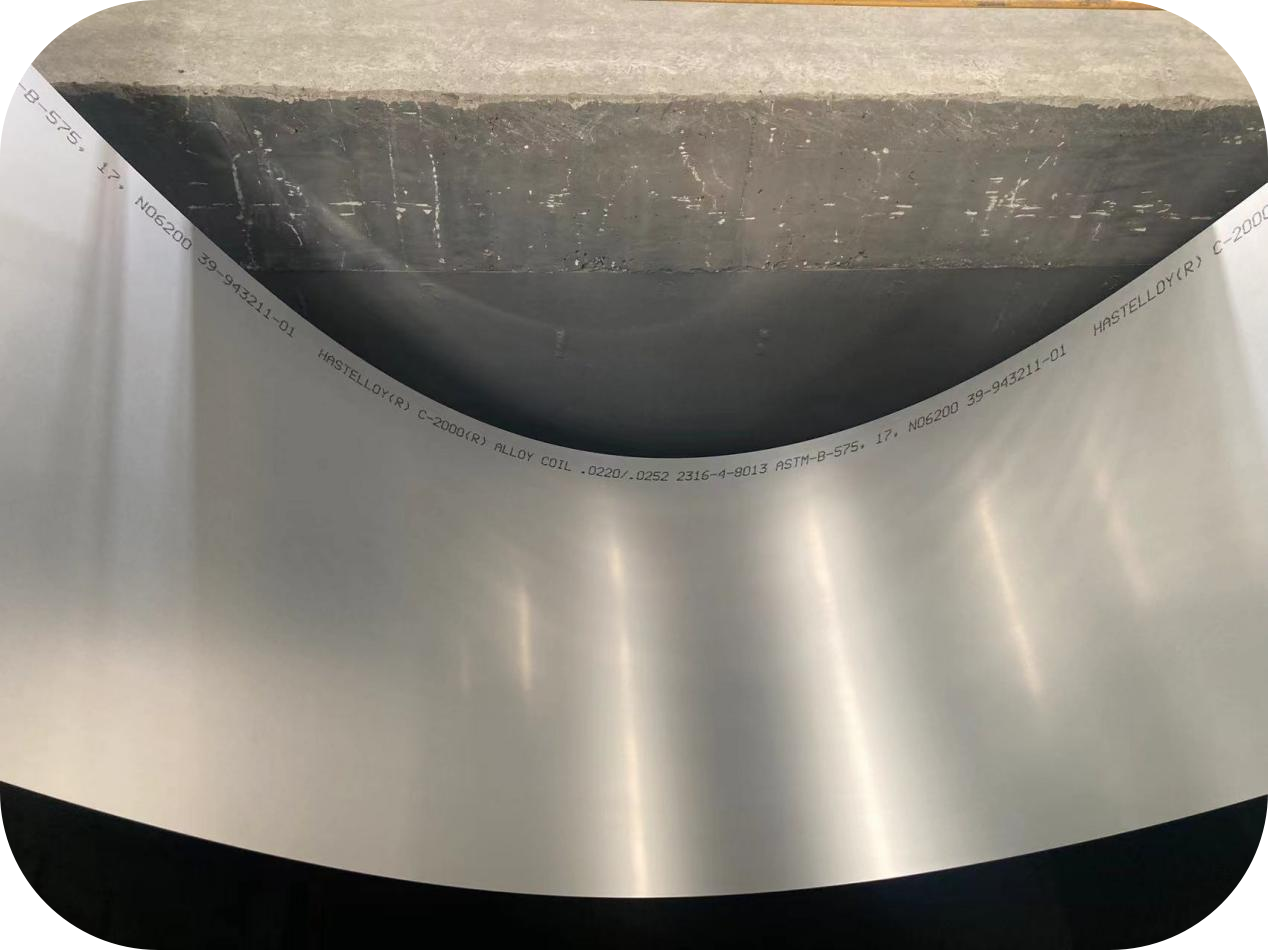

In industrial settings, plate heat exchangers often face two typical problems: Plates bulge or leak under high-pressure and high-temperature conditions due to insufficient thickness, leading to production line downtime. Over-thickening plates, while enhancing structural stability, significantly increases thermal resistance, resulting in decreased heat transfer efficiency and increased energy consumption. The selection of plate thickness is not simply a matter of "thicker for stability, thinner for savings." Instead, it requires a comprehensive trade-off based on operating conditions, material properties, and structural design. It is a key link in ensuring the long-term reliable operation of the equipment. This article will start from the core functions of thickness, then break down the key dimensions of selection and common misunderstandings to provide professional and practical selection ideas for industrial scenarios. 1. The Three Core Functions of Plate Thickness: Beyond Structural Support Plate thickness is a core variable in the safety-efficiency-lifetime triangle balance of plate heat exchangers. Its role extends far beyond mere pressure resistance, specifically reflected in three aspects: Structural Load-Bearing Capacity: As the core component resisting internal media pressure, the thickness must ensure that the plates do not undergo plastic deformation or fracture under the design pressure. Especially during fluctuating operating pressures, sufficient thickness can prevent plate failure issues like bulging or cracking due to instantaneous overload. Corrosion Allowance Reserve: For media containing corrosive substances such as acids, alkalis, or chloride ions, the thickness needs to reserve a certain corrosion allowance – even if the plate surface thins due to corrosion during long-term service, the remaining thickness must still meet structural load-bearing requirements, preventing leaks caused by corrosion penetration. Heat Transfer Efficiency Adaptation: Plate thickness directly affects thermal resistance. Thinner plates mean lower thermal resistance and higher heat transfer efficiency. However, excessive thinning may lead to insufficient plate stiffness, requiring additional support structures which can offset the efficiency advantages. Therefore, a balance must be found between thinning for efficiency and structural stability. 2. The Four Core Dimensions of Plate Thickness Selection Thickness selection needs to revolve around the four core dimensions of operating parameters, media characteristics, material properties, and structural design – all requiring deep alignment with the actual application scenario: Operating Pressure and Temperature: Determining the basic threshold for thickness. Low-Pressure, Ambient Temperature Conditions (e.g., civil heating, food cooling systems, design pressure ≤ 1.6 MPa, temperature ≤ 80°C): The media impose low requirements on the mechanical properties of the material. Plates do not need to be overly thick, and thinner specifications can be prioritized to optimize heat transfer efficiency. High-Pressure, High-Temperature Conditions (e.g., chemical reactor cooling, high-temperature steam heat exchange, design pressure > 2.5 MPa, temperature > 200°C): High temperatures cause a decrease in the allowable stress of the material, and high pressure requires higher structural load-bearing capacity. Thicker plates must be selected, while prioritizing high-strength materials to avoid efficiency loss from excessive thickening. Media Corrosiveness: Determining the redundancy reserve for thickness. Mildly Corrosive Media (e.g., tap water, edible oil, neutral process fluids): The material's inherent passivation film can resist corrosion, and no additional corrosion allowance is needed. Thickness selection primarily meets structural load-bearing and efficiency requirements. Moderately/Severely Corrosive Media (e.g., hydrochloric acid, sulfuric acid, seawater, sour crude oil containing sulfur): It is necessary to evaluate the corrosion rate based on media concentration and temperature. Options include either selecting thicker plates to reserve a corrosion allowance, or directly switching to materials with stronger corrosion resistance (e.g., titanium alloy, nickel-based alloys). Note: for some highly corrosive media (e.g., concentrated nitric acid), the corrosiveness to ordinary materials is so strong that merely increasing thickness cannot meet service life requirements; switching to specialized corrosion-resistant materials is a better solution. Material Mechanical Properties: Determining the strength redundancy for thickness. Common Materials (e.g., 304, 316L stainless steel): Moderate mechanical properties; require selecting relatively thick specifications to meet load-bearing requirements in low to medium-pressure conditions. High-Strength Materials (e.g., titanium alloy, nickel-based alloys): Yield strength is significantly higher than ordinary stainless steel. Under the same pressure, thinner plates can be selected, balancing both structural stability and heat transfer efficiency. Plate Structural Design: Determining the stiffness assistance for thickness. High Stiffness Structures (e.g., large-angle herringbone corrugations): The corrugations effectively distribute media pressure and enhance the overall stiffness of the plate, allowing for the selection of thinner plates under the same conditions. Low Stiffness Structures (e.g., straight corrugations, shallow corrugations): Weaker stiffness, requiring increased thickness to enhance structural stability and prevent plate deformation under pressure. 3. Summary: Core Principles of Thickness Selection Plate heat exchanger plate thickness selection should follow three core principles: Condition Priority Principle: Use pressure, temperature, and corrosiveness as the main factors to determine the basic thickness threshold and corrosion allowance. Material Adaptation Principle: Considering the mechanical properties and corrosion resistance of the material, prioritize selecting thinner specifications to optimize efficiency while meeting load-bearing requirements. Efficiency and Cost Balance Principle: Avoid over-thickening or blind thinning. Achieve a balance between thinning for efficiency and structural stability through structural optimization (e.g., corrugation design). In practical selection, it is recommended to refer to standards such as GB/T 16389 "Plate Heat Exchangers" and ASME VIII-1. If necessary, verify plate stress distribution through analysis to ensure the thickness choice meets both safety requirements and considers economy and efficiency. If you need thickness selection analysis for specific conditions (such as high-temperature, high-pressure steam exchange, or highly corrosive media handling), or need to match the selection with specific materials (such as stainless steel, titanium alloy, nickel-based alloys), please feel free to contact us.

For example, in the food processing industry handling neutral media (like milk, juice), plates do not need a large corrosion allowance, allowing the selection of thinner specifications to improve heat transfer efficiency. In the chemical industry handling concentrated hydrochloric acid or high-temperature alkali solutions, ensuring corrosion allowance and structural strength takes priority, requiring a more conservative thickness selection.

Pressure and temperature are the primary constraints for thickness selection. They jointly influence the allowable stress of the material and must be considered simultaneously:

In short, the more demanding the conditions (higher pressure, higher temperature), the higher the structural redundancy the plates need, and the thickness selection must be increased accordingly.

The corrosiveness of the media directly determines whether the thickness needs to reserve a corrosion allowance. Selection should be based on corrosion intensity classification:

For example, in seawater desalination systems, ordinary stainless steel, even if thickened to 1.0mm, will still fail rapidly due to chloride ion corrosion. Selecting titanium alloy plates, even with a thickness of only 0.5mm, can achieve stable service for over 10 years.

The inherent load-bearing capacity (yield strength, tensile strength) of different materials varies, directly affecting thickness selection under the same operating conditions:

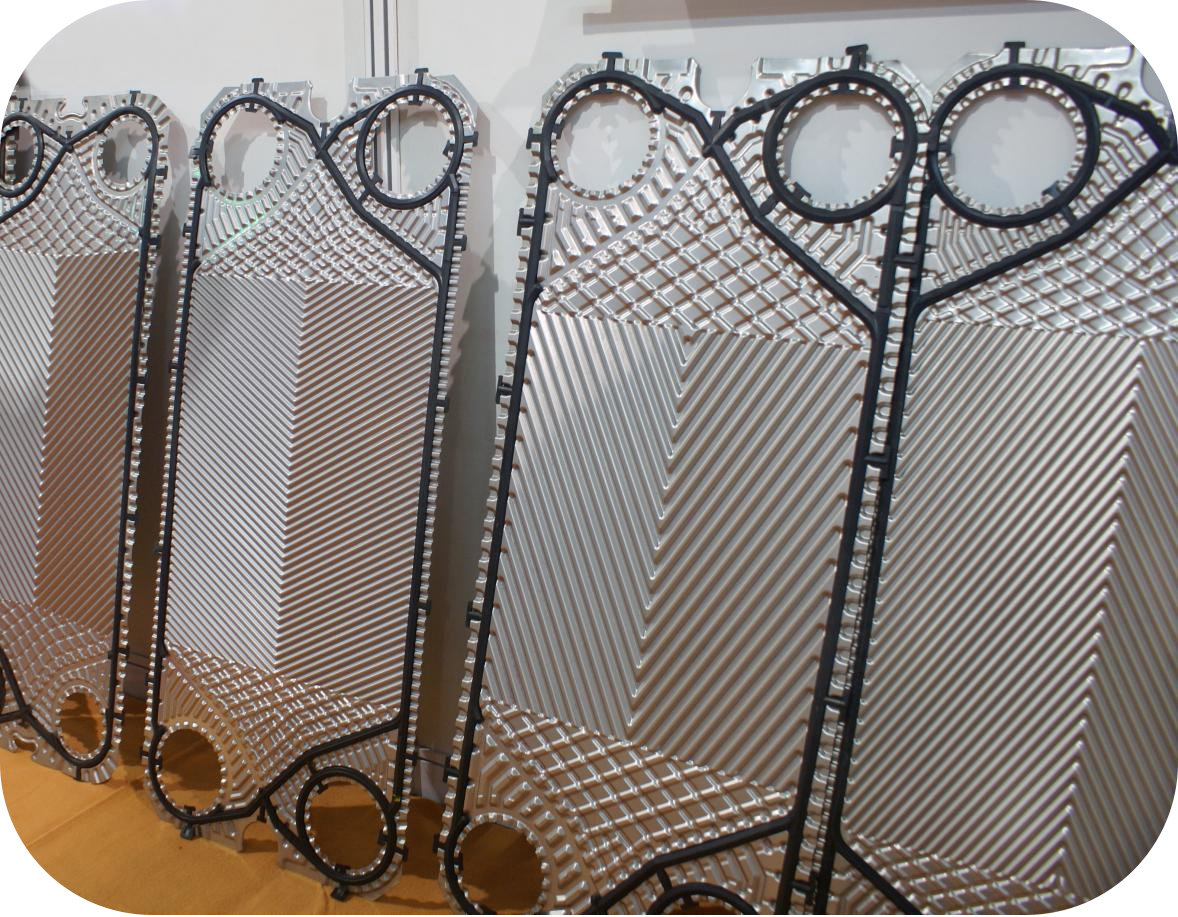

The plate's corrugation pattern (e.g., herringbone, straight, zigzag) acts like a built-in skeleton, potentially reducing reliance on thickness by optimizing structural stiffness:

In short, the more reasonable the plate structure design, the stronger its compensating effect on thickness, and the easier it is to achieve a balance between thinning for efficiency and structural stability.