Core Differences Between C-2000 and C-276 Alloys

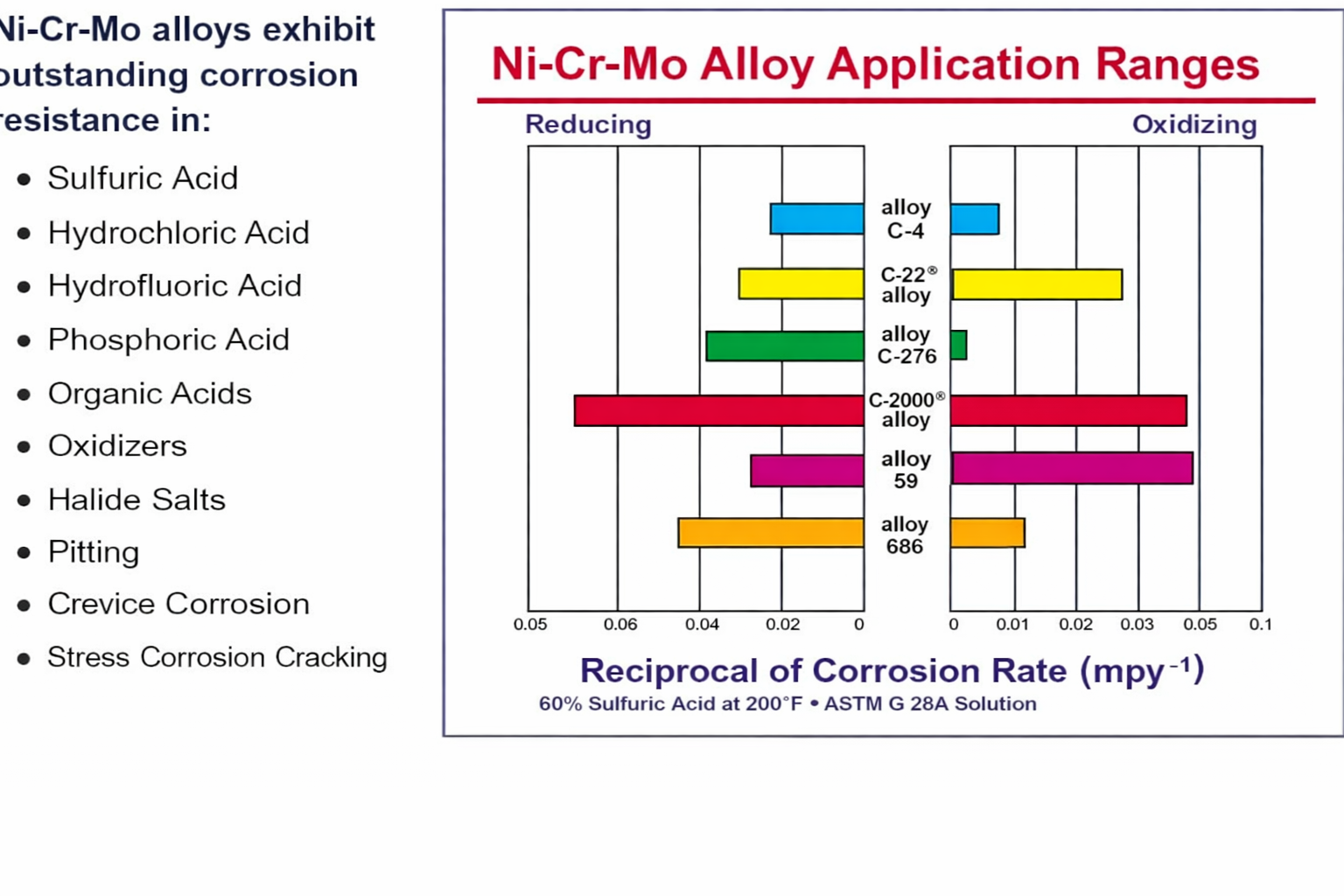

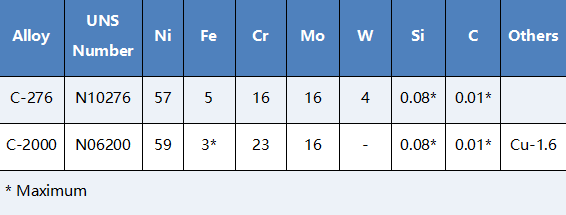

Avoid Pitfalls in Material Selection: Core Differences Between C-2000 and C-276 Alloys Summary In extreme corrosive environments, such as chemical processing, marine engineering, and nuclear power, HASTELLOY C-276 has long been the "benchmark" nickel-based corrosion-resistant alloy. However, with the increasing complexity of industrial media (high-concentration acids, harsh chlorine-containing systems, high-temperature and high-pressure conditions), a more targeted upgraded product—HASTELLOY C-2000 (UNS N06200)—has gradually stood out. With its unique composition design and comprehensive performance breakthroughs, it surpasses C-276 in critical corrosion-resistant scenarios. Today, we will delve into the core advantages of C-2000 over C-276 from a technical perspective. I. Ingenious Composition: Copper Element Empowerment, Specifically Tackling Acid Corrosion Challenges The most fundamental difference between C-2000 and C-276 lies in the deliberate addition of copper in C-2000—a design directly addressing the most common industrial pain point: sulfuric acid corrosion. Looking at the composition tables, C-2000 contains 1.6% copper, whereas C-276 contains no copper. Copper can form a stable passive film in sulfuric acid media, significantly reducing the corrosion rate. In sulfuric acid environments with concentrations up to 80%, C-2000 maintains a consistently low corrosion rate in the range of 0.1-0.5 mm/y, demonstrating excellent stability even under boiling conditions. In contrast, the corrosion rate of C-276 increases significantly in high-concentration sulfuric acid (e.g., above 70%), making it difficult to meet long-term service requirements. Furthermore, C-2000 maintains a high chromium content of 23% (comparable to C-276), ensuring corrosion resistance in oxidizing media (such as systems containing ferric ions or dissolved oxygen). A molybdenum content of 16% enhances resistance to non-oxidizing acids (like hydrochloric acid), creating a synergistic triple effect of "chromium + molybdenum + copper" for corrosion resistance. This is something the single corrosion-resistant system of C-276 cannot match. Main Chemical Composition (Weight Percentage) II. Comprehensive Corrosion Resistance Upgrade: Covering More Demanding Corrosive Scenarios 1. Broader Acid Media Corrosion Resistance Range, Superior Performance in Extreme Conditions The advantages of C-2000 are particularly prominent in two core industrial corrosive media: hydrochloric acid and sulfuric acid: Hydrochloric Acid Environment: In hydrochloric acid concentrations ≤10%, the corrosion rate of C-2000 is far lower than that of C-276. Even when the temperature rises to 175°F (79°C), C-2000 maintains an ultra-low corrosion rate of <0.1 mm/y. Under the same conditions, the corrosion rate of C-276 approaches the critical value of 0.5 mm/y. Mixed Acid Systems: In the harsh mixed acids commonly found in the chemical industry, such as "Green Death (11.5% H₂SO₄ + 1.2% HCl + 1% FeCl₃ + 1% CuCl₂)" and "Yellow Death (4% NaCl + 0.1% Fe₂(SO₄)₃ + 0.021M HCl)," C-2000 performs even more impressively. In the Yellow Death solution, even at temperatures as high as 150°C (302°F), C-2000 shows no pitting, with a critical crevice temperature reaching 95°C. In contrast, C-276 is prone to localized corrosion risks in similar high-temperature mixed acids. 2. Superior Pitting/Crevice Corrosion Resistance, More Reliable in Chlorine-Containing Environments Chloride-induced pitting and crevice corrosion are among the main causes of chemical equipment failure. C-2000 achieves a key breakthrough over C-276 in this area: According to ASTM G48 standard testing (acidified 6% FeCl₃ solution, 72 hours), the Critical Crevice Temperature (CCT) of C-2000 is as high as 80°C (176°F), whereas that of C-276 is only 55°C (131°F). This means that in chlorine-containing environments below 80°C, C-2000 almost never experiences crevice corrosion, while C-276 may suffer corrosion failure above 55°C. This advantage is particularly important in practical application scenarios. For example, in chlorine-containing process streams or seawater cooling systems, C-2000 can operate stably at higher temperatures without the need for additional anti-corrosion measures (such as lining or coatings), thereby reducing equipment complexity and maintenance costs. 3. Zero Corrosion in Seawater Environment, the Preferred Choice for Marine Engineering In scenarios such as marine transportation and offshore oil drilling platforms, seawater crevice corrosion has long been a challenge for engineers. Test data from LaQue Laboratory shows: C-2000, after 180 days of testing in both stagnant and flowing seawater at 29°C, showed zero corrosion spots, zero corrosion depth, demonstrating perfect crevice corrosion resistance. C-276, however, exhibited 2 corrosion spots in stagnant seawater, with a maximum corrosion depth of 0.13 mm. Although it showed no corrosion in flowing seawater, its protective capability in stagnant conditions is still inferior to C-2000. This difference makes C-2000 more reliable than C-276 for critical components in marine engineering, such as seawater heat exchangers and drilling platform connectors. Corrosion Rates of Hastelloy C-Series Alloys in Various Inorganic Acids III. Application Scenarios: Areas Where C-2000 Offers Greater Replacement Value Based on the above advantages, C-2000 is more worthy of priority selection over C-276 in the following scenarios: High-Concentration Sulfuric Acid Systems: Such as sulfuric acid production, pickling processes, fertilizer manufacturing, etc. In sulfuric acid environments with concentrations ≤80%, the service life of C-2000 can be extended by over 30% compared to C-276. Chlorine-Containing Mixed Acid Conditions: Such as chemical intermediate synthesis, metallurgical pickling, electroplating waste liquid treatment, etc., involving chlorine-containing systems with oxidants like FeCl₃ and CuCl₂. Marine and Seawater Applications: Seawater coolers, offshore platform structural components, ship desulfurization systems, etc. High-Temperature and High-Pressure Corrosive Environments: Such as nuclear power auxiliary equipment, petrochemical hydrogenation reactors, high-temperature acid transportation pipelines, etc. Conclusion: C-2000 is Not a "Replacement" but an "Upgrade" HASTELLOY C-276, as a classic corrosion-resistant alloy, continues to play a vital role in many scenarios today. However, C-2000 achieves a performance upgrade in more severe corrosive environments through "copper element empowerment + optimized chromium-molybdenum ratio." It is not simply a replacement for C-276 but provides the industry with a high-end option offering "higher corrosion resistance thresholds, broader application ranges, and longer service life." Our company also stocks C-2000 materials of U.S. Hastelloy origin specifically for the plate heat exchanger industry, offering an additional choice for exceptionally demanding conditions. If you have any needs, please feel free to call for consultation.