Introduction to UNS N08330 Material

Introduction to UNS N08330 Material

Basic Information

Type: UNS N08330 is an austenitic heat- and corrosion-resistant alloy primarily composed of nickel, chromium, and iron.

Equivalent Grades: Incoloy Alloy 330, W. Nr. 1.4886.

Chemical Composition

Nickel (Ni): Typically 34%-37%, the primary element for forming austenite, enhancing the alloy’s strength, toughness, corrosion resistance, and high-temperature stability.

Chromium (Cr): 17%-20%, forms a dense oxide layer on the surface, significantly improving oxidation and corrosion resistance.

Iron (Fe): Balance, serving as the matrix of the alloy, providing fundamental strength and toughness.

Silicon (Si): 0.75%-1.50%, notably enhances oxidation resistance, particularly in carburizing atmospheres.

Manganese (Mn): ≤2.0%, improves strength and toughness. Proper Mn content helps prevent hot cracking during welding.

Phosphorus (P), Sulfur (S): Both ≤0.030%, considered harmful impurities. Excessive content reduces toughness and corrosion resistance.

Physical Properties

Density: Approximately 8.0 g/cm³, offering a moderate density that ensures strength without excessive weight.

Melting Point: 1318-1427°C, the high melting point provides excellent thermal stability in high-temperature environments, withstanding heating and cooling cycles.

Specific Heat Capacity: 0.46 J/(kg·K) at 0-100°C, remaining relatively stable, helping to minimize thermal stress during temperature changes.

Thermal Conductivity: 12.6 W/(m·K) at 100°C and 19.7 W/(m·K) at 500°C. The increasing thermal conductivity with temperature allows efficient heat transfer, preventing localized overheating and improving thermal efficiency.

Electrical Resistivity: 1.02 Ω·mm²/m at 20°C, the relatively high resistivity makes UNS N08330 suitable for electrical applications requiring controlled resistance.

Young’s Modulus: 196 GPa at 20°C, reflecting high rigidity and resistance to elastic deformation.

Magnetic Properties: Non-magnetic, making it suitable for applications with strict magnetic requirements, such as electronics and medical devices.

Material Characteristics

High-Temperature Performance: Can be used under various high-temperature heating conditions up to 1035°C, with some applications reaching 1204°C (2200°F). Maintains excellent strength and stability at elevated temperatures.

Corrosion Resistance: Resistant to carburization and nitridation, with outstanding corrosion resistance in oxidizing and sulfur-containing environments. Highly resistant to chloride-induced stress corrosion cracking.

Thermal Shock Resistance: Withstands rapid heating and cooling cycles without cracking or damage, capable of enduring thermal shock from liquid quenching.

Machinability: Easily machinable using conventional tools for forming, cutting, and drilling. Suitable for hot working (rolling, forging, extrusion) and cold working (cold drawing, cold rolling) to achieve high precision and surface quality.

Metallurgical Stability: Maintains a fully austenitic structure at all temperatures without sigma-phase embrittlement. The stable microstructure ensures long-term performance in high-temperature environments.

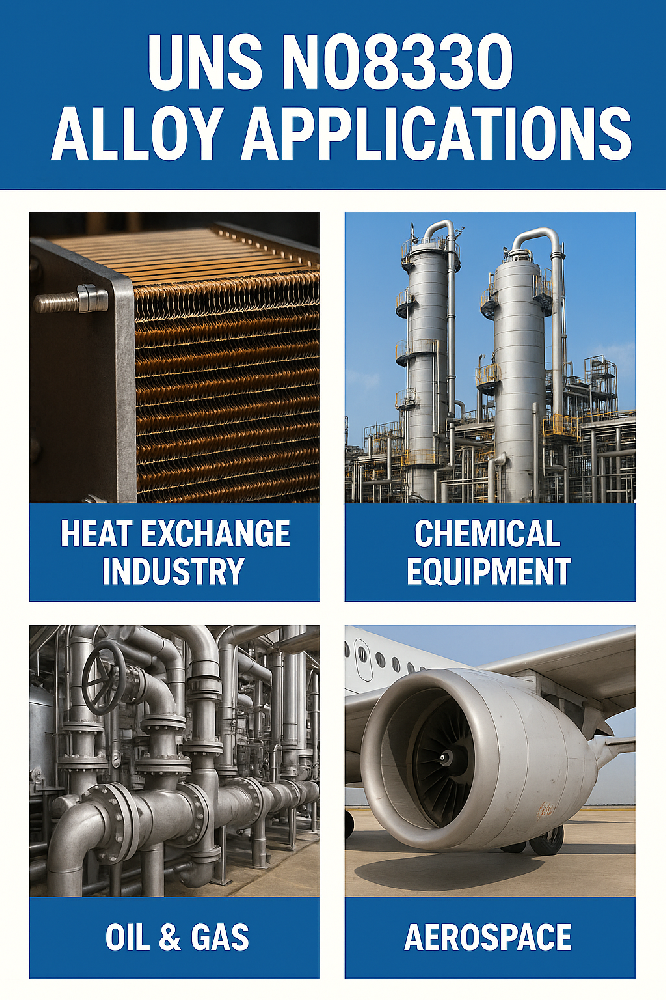

Applications

Heat Treatment Industry: Widely used in furnace components such as retorts, furnace grates, conveyor belts, and radiant tubes, capable of withstanding harsh high-temperature conditions.

Chemical Equipment: Used in reactors, heaters, and heat exchangers, especially in corrosive media processing, extending equipment service life.

Oil & Gas: Applied in high-temperature corrosive environments in refining and petrochemical industries, including piping, valves, and towers in cracking units.

Aerospace: Used in high-temperature components and thermal protection systems, leveraging its thermal stability and corrosion resistance for safe operation in extreme conditions.