Hastelloy C-276 in PTA Units

Purified terephthalic acid (PTA) is an important raw material for the production of polyester fibers, resins, and other products. In PTA production units, the process involves various corrosive media and complex operational conditions, which impose high demands on the material properties, such as corrosion resistance and high-temperature performance. Hastelloy C-276, with its outstanding properties, has been widely used in PTA units.

1. PTA Process and Corrosive Environment

The PTA production process mainly consists of two stages: oxidation and purification. During the oxidation process, p-xylene is used as the raw material and is oxidized in an acetic acid solvent under the action of catalysts (such as cobalt acetate and manganese acetate) with air to produce crude terephthalic acid. This process involves various corrosive substances, such as acetic acid and bromide ions (used as co-catalysts). The purification process further refines the crude terephthalic acid, during which the mother liquor contains acidic and corrosive components.

2. Performance Advantages of Hastelloy C-276

Hastelloy C-276 is a nickel-molybdenum-chromium-tungsten alloy with the following properties that make it suitable for PTA units:

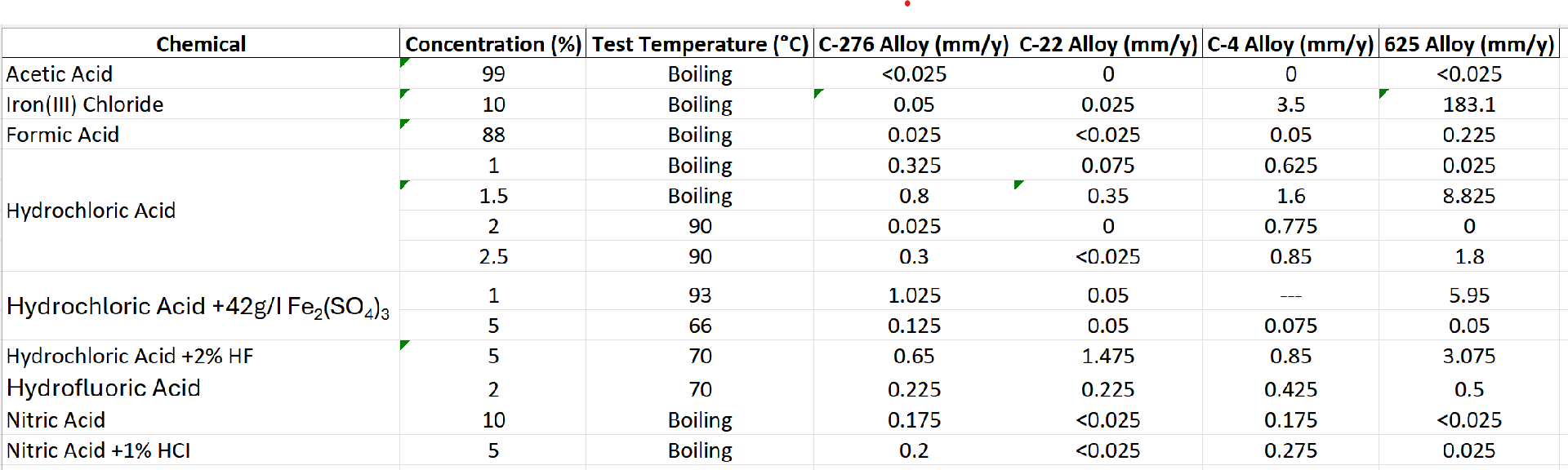

1. Excellent Corrosion Resistance: It is highly resistant to a variety of acidic media, including organic acids such as acetic acid. It also shows excellent tolerance to bromide ion corrosion in the oxidation process. In environments containing chloride ions, its high molybdenum and chromium content effectively prevents pitting and crevice corrosion, which is crucial in the complex chemical environment of PTA units.

2. Good High-Temperature Resistance: Under the high-temperature conditions of the PTA oxidation reaction (typically around 180–200°C), Hastelloy C-276 maintains stable performance without significant loss of material strength or deformation, ensuring the normal operation of the equipment.

3. Excellent Stress Corrosion Cracking Resistance: In PTA units, equipment and piping are subjected to both internal pressure from the media and corrosive conditions. Hastelloy C-276 effectively resists stress corrosion cracking, thereby extending the service life of the equipment.

3.Specific Applications in PTA Units

1. Oxidation Reactor: The oxidation reactor is the core equipment in PTA production. Components such as the agitator, cooling coils, and baffles inside the reactor are often made of Hastelloy C-276. The agitator comes into full contact with the corrosive media during its rotation, and the corrosion resistance of C-276 ensures long-term stable operation, maintaining effective mixing and promoting uniform reactions. The cooling coils are required to effectively remove reaction heat in a high-temperature, corrosive environment, and the high-temperature and corrosion resistance of C-276 make it an ideal material for this application.

2. Piping System: In PTA units, pipes used to transport corrosive media such as acetic acid, oxidation mother liquor, and purified mother liquor are made of Hastelloy C-276. These pipes can withstand the corrosion of the media over long periods, preventing leaks and ensuring the continuity of the production process. For example, pipes connecting the oxidation reactor to subsequent separation and purification equipment made from C-276 significantly reduce maintenance and replacement frequency.

3. Heat Exchangers: Heat exchangers are used in PTA units to heat or cool process media. Hastelloy C-276 is used in the tube bundles and shells of heat exchangers. During the heat exchange process, it resists corrosive components that may be present in the heating or cooling media, while maintaining excellent thermal conductivity at high temperatures, improving heat exchange efficiency and ensuring the stability and reliability of the entire heat exchange process.

4. Filtration Equipment: In the purification process, some critical components of filtration equipment, such as filter elements and screens that come into contact with the corrosive mother liquor, are made from Hastelloy C-276. It effectively filters impurities in a corrosive environment, ensuring the purity of PTA products, while the material itself is not damaged by corrosion, reducing maintenance costs for the filtration equipment.

The application of Hastelloy C-276 in PTA units is of great significance for ensuring the stable and efficient operation of the plant. Its excellent corrosion resistance, high-temperature resistance, and stress corrosion cracking resistance enable it to perform reliably in the harsh conditions of PTA units over long periods. Although the material is relatively expensive, in the long run, it reduces issues such as frequent equipment replacements and maintenance-related production downtime, thereby improving the economic efficiency and safety of PTA production.