Introducing N06625: A Key Material in Aerospace Excellence

At Ruisen, we take pride in presenting a standout product that has earned its reputation for exceptional performance—N06625. This nickel-chromium-iron alloy (Inconel 625) plays a critical role in the aerospace industry, thanks to its remarkable properties.

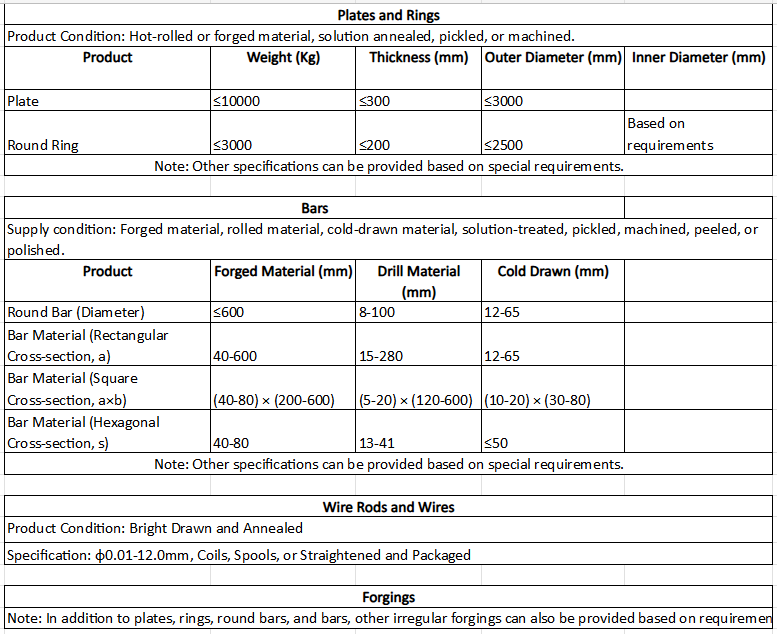

Specifications and Standards

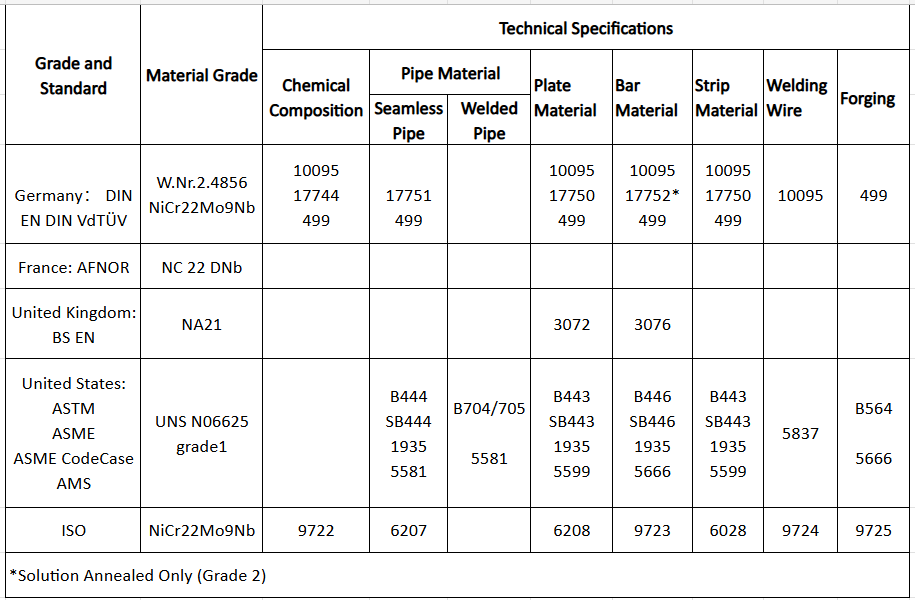

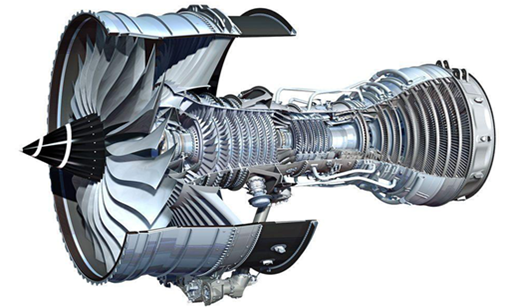

In aerospace, aircraft engines are often referred to as the "heart" of an aircraft, operating under extreme conditions of high temperature, pressure, and stress. N06625 alloy is widely used in manufacturing critical engine components such as turbine disks, blades, and combustion chambers.

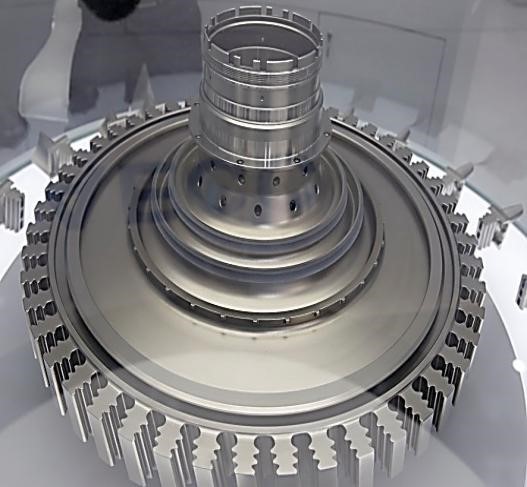

Turbine Disks: These components endure immense centrifugal forces and high-temperature gas impacts during high-speed rotation. N06625 alloy’s high strength and heat resistance ensure stable operation in extreme environments, maintaining efficient power output.

Turbine Blades: Operating at extremely high temperatures, turbine blades benefit from the alloy’s resistance to high-temperature corrosion and thermal stress. Its excellent fatigue resistance prevents cracks caused by high-frequency vibrations, ensuring long-term engine reliability.

Combustion Chambers: These face high-temperature flames and corrosive gases. N06625’s oxidation and corrosion resistance at high temperatures make it the ideal material, enhancing combustion efficiency and engine performance.

Applications in Aircraft Structures and Landing Gear

N06625 alloy also finds applications in aircraft fuselages and landing gear.

Aircraft Structures: High-stress or high-temperature components, such as frames and connectors in hot zones, utilize N06625 for its strength and corrosion resistance. This enhances the structural integrity and durability of the fuselage, ensuring flight safety.

Landing Gear: During takeoff and landing, landing gear experiences significant impact and friction. N06625 alloy’s strength, toughness, and fatigue resistance enable it to meet these performance demands, ensuring reliable support. Its corrosion resistance extends its lifespan even in harsh airport environments.

Essential in Fuel and Hydraulic Systems

N06625 alloy is indispensable in aerospace fuel and hydraulic systems.

Fuel Systems: Pipes, pumps, and valves made from N06625 resist corrosion from long-term contact with fuels, maintaining stable fuel transport and system sealing.

Hydraulic Systems: Operating under high pressure, hydraulic components like cylinders and pipes require exceptional strength and sealing. N06625’s high-pressure stability and machinability make it ideal for precision hydraulic system parts, ensuring reliable control of aircraft operations.

Role in Spacecraft Manufacturing

N06625 alloy is also used in high-temperature structural and connecting components in spacecraft.

Propulsion Systems: Components exposed to hot gases, such as nozzle parts and combustion chamber liners, rely on N06625 for its ability to endure high temperatures and complex mechanical conditions during launches and in-orbit operations.

External Structures: Spacecraft external parts subjected to radiation, temperature fluctuations, and micrometeoroid impacts benefit from N06625’s comprehensive performance, ensuring long-term stability in harsh environments.

Driving Aerospace Innovation

The extensive use of N06625 in aerospace significantly enhances aircraft performance, ensures safety, and drives advancements in aerospace technology. As one of Ruisen’s flagship products, we offer a comprehensive inventory of N06625 in various specifications. For technical inquiries, please feel free to contact us.