Application of Super Stainless Steel 254SMO in Alumina Refining Processes

Introduction to Alumina

Alumina (Al₂O₃) is a compound with high hardness, widely used in various industrial fields.

Bauxite is the main ore source for alumina. After initial processing like ore beneficiation, alumina is extracted through methods such as Bayer process, the sintering process, or a combination of techniques. Of these, the Bayer process is the most widely used for alumina production. This method is particularly effective for high-quality bauxite and works by dissolving alumina from the bauxite using a sodium hydroxide solution. It then undergoes several complex stages, including seeding decomposition, to produce the fianl alumina product.

Applications:

Metallurgical-Grade Alumina:

Approximately 95% of alumina is used for aluminum electrolysis, serving as a critical intermediate in producing metallic aluminum.

Specialty Alumina:

Plays significant roles in ceramics, chemical industries, and pharmaceuticals. For instance:

Ceramic Industry: Alumina ceramics exhibit high strength, hardness, temperature resistance, and wear resistance, used to manufacture mechanical parts, cutting tools, etc.

Chemical Industry: Alumina acts as a catalyst carrier, enhancing the activity and stability of catalysts.

Application of 254SMO in Alumina Refining

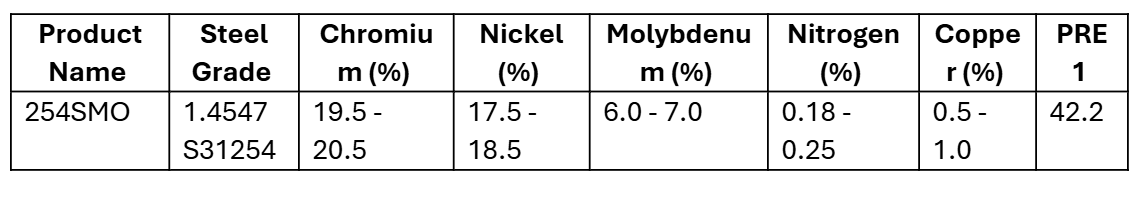

254SMO is a high-performance super austenitic stainless steel with exceptional corrosion resistance, high strength, and excellent workability. Its chemical composition includes approximately 20% chromium, 18% nickel, and 6% molybdenum, endowing it with superior performance in highly corrosive environments.

Key Features in Application:

Resistance to Corrosive Environments:

Alumina refining involves sodium aluminate solutions containing high concentrations of NaOH and chloride ions, posing stringent requirements on material corrosion resistance.

Research shows that 254SMO exhibits excellent corrosion resistance under conditions such as 100°C, 1.35 MPa, 20% NaOH concentration, and 5000 ppm chloride ions. This makes it suitable for critical processes like solution heat exchange, mother liquor preheating, alkaline treatment, and steam condensation.

Advantages of 254SMO:

Advantages of 254SMO:

High Temperature and Alkaline Brittleness Resistance:

The high molybdenum and low carbon content in 254SMO provide excellent resistance to high-temperature and alkaline brittleness, ensuring long-term stable operation in harsh conditions.

Superior Mechanical Properties:

Its stress corrosion cracking resistance makes it an ideal choice for alumina refining processes requiring high durability.

In summary, the application of 254SMO in alumina refining processes is primarily due to its outstanding corrosion resistance, high-temperature performance, and resistance to stress corrosion cracking. These attributes make it an optimal material for the industry.